Workpiece carrier or pallet conveyors are used in numerous industries to optimize assembly lines. A major advantage of modern transfer systems with workpiece carriers is their high degree of modularity. They can be flexibly expanded and optimally integrated into existing production lines. They thus enable cost-efficient automation – both for small parts and for large products weighing up to 150 kg.

In this article, we will show you the wide range of possibilities offered by our workpiece carrier systems.

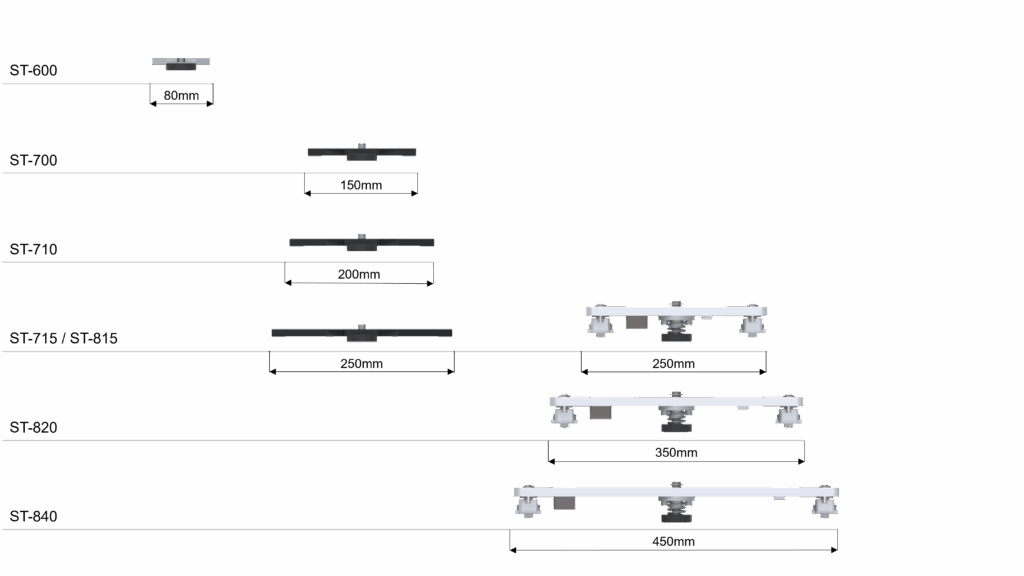

Workpiece carriers – custom sizes

We can manufacture workpiece carriers according to customer specifications, tailored to your requirements. Whether for small components or large workpieces, our high-quality carriers offer maximum flexibility.

The available sizes range from 80 × 80 mm to 500 × 2000 mm, with individual drilling patterns for your product mounting or directly with mountings for your products.

The width of the workpiece carriers is matched to the respective system width and enables precise alignment with our centering module. If no centering module is used, the workpiece carrier can also extend beyond the system width. The length can be freely selected – we would be happy to advise you on your desired dimensions.

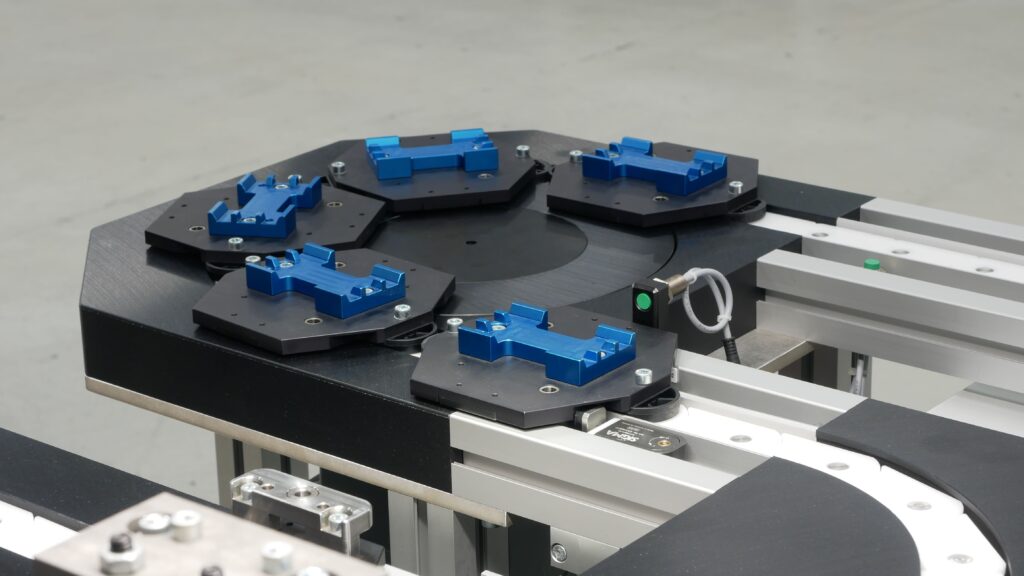

Workpiece carriers – Shapes

Our workpiece carriers are available in square, rectangular, and curve-compatible shapes. (Curve-compatible carriers are only available for the ST-600 and ST-700-715 system sizes).

The curved version allows for accumulation in curves, enabling efficient use of the system. Workpiece carriers for system sizes ST-815-840, on the other hand, cannot be accumulated in curves.

Workpiece carriers – Weight classes

We distinguish between two variants:

- Light workpiece carriers (up to 8 kg) for system sizes ST-600 and ST-700-715

- Heavy workpiece carriers (8–150 kg) for system sizes ST-815-840

In the lightweight version, the total weight of the workpiece, holder, and carrier is carried directly by the transfer chain. In the curves, the workpiece carrier plate is additionally supported by two lateral slide plates, which ensure stable and smooth running.

In the heavy-duty version, the load is carried by swivel casters that rest on the side profiles. The chain is only subjected to a spring load of approx. 2 × 40 N.

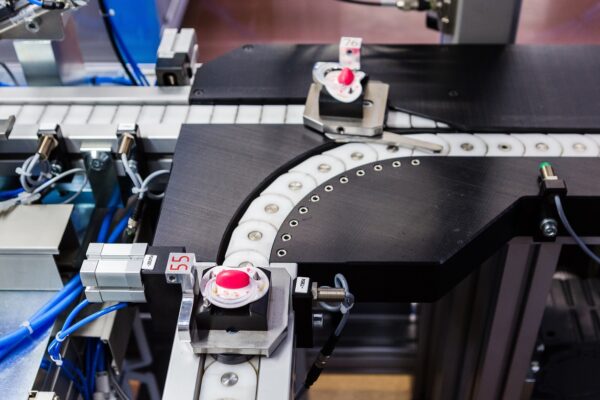

Workpiece carrier in the transfer system

In the transfer system, the workpiece carriers are stopped by pneumatic or electric stoppers and precisely centered if necessary. Depending on the product weight, 1 to 10 workpiece carriers can be accumulated at a stopper – for maximum efficiency and process reliability in your assembly system.

Process optimization for your company

Is there a process in your company that you would like to optimize? Our experts at Rodotec AG and Sigma will support you with their expertise, experience, and customized solutions.